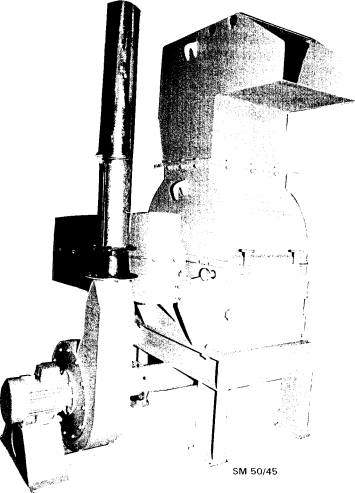

WERY - cutting mills

with cyclone-separator

are accepted and approved crushing machines

effective in industry and recycling technology

Advantages:

Robust construction

Easy handling

Low maintenance

Multi-purpose applications

Powerful and efficient

Low cost

Applications:

Industry

Recycling companies: Milling and crushing of thermoplastic plastics like die-casting, extrusion waste, profiles, plates, foils, fibres, hollow parts as bottles, buckets, cans.

DSD-compounds, abrasive products like fibre-glass reinforced plastics.

Construction:

Enclosure in heavy robust sheet steel-electrowelded construction.

Milling space with exchangeable wear- resistant steel armour plates.

The upper enclosure is easy to open, simple access to all milling tools and armour plates.

The large dimensioned rotor with main shaft, rotor disks and knives works by scissor-type principle.

The adjustable rotor knives guarantee a constant cutting circle and an even running with optimal throughput.

The presetable cutting- and stator-knives minimize operation interruptions.

The heavy rotor sits in amply sized ball joint bearings in dust-proof pedestal bearing enclosure.

The strainer in the lower enclosure, a perforated-, quadrat- or ellipse-stainer with stainer-frame, is easy to change through the maintenance door.

Mill, bearing and drive are mounted on a buckling resistant steel-base.

The e-drive has thermal winding cover.

The control mode while feeding avoids an overstressing of the mill.

Limit switch and special safeguards prevent accidents while service and maintenance.

- More information on WERY - cutting mills with cyclone separator